Camisasca Automotive Manufacturing is a family-owned and operated world class leader in the production of premier Stainless Steel and Aluminum parts and accessories for over 40 years. Specializing in stamping, laser-cutting, polyurethane-doming, and other unique graphic applications, our ISO certified quality system & engineering capabilities ensure 100% control of the in house production process.

WHY WE ARE DIFFERENT

It all began in 1982, when our founder, Henry, looked at the ordinary license plate frame and saw opportunity to improve. With the simple but powerful belief—“I can do this better”—he set out to reinvent something as overlooked as the license plate frame. That spark of innovation became our guiding mantra. From that first product to the expansive capabilities we offer today, our team has never stopped asking, “What’s next?” We thrive on pushing boundaries, bringing bold ideas to life within our cutting-edge U.S. facilities. Here, premium materials meet precision craftsmanship and advanced technology—resulting in products that don’t just compete, but lead.

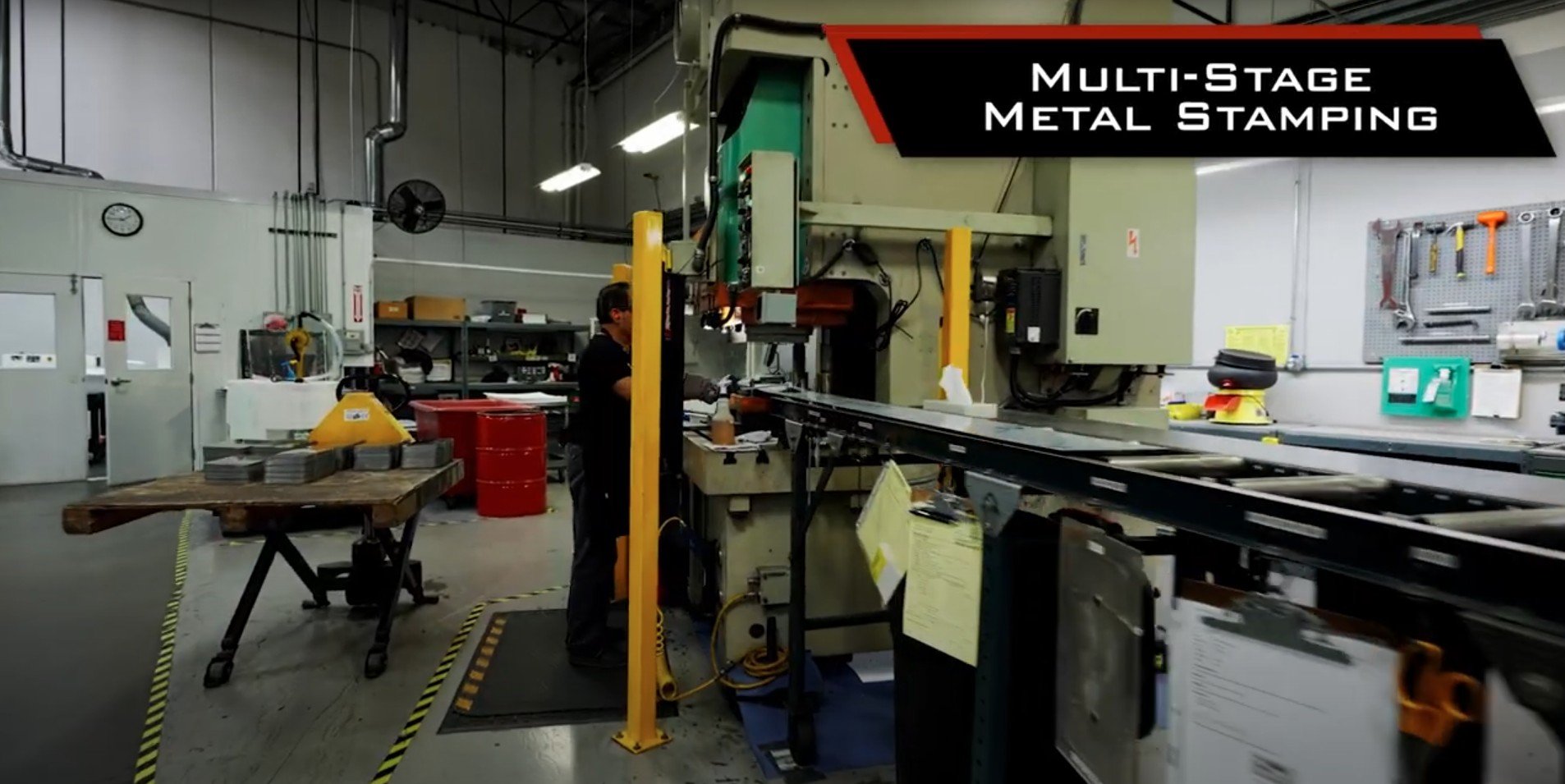

PRODUCTION PROCESSES

With a 40+ year history in automotive manufacturing, we have learned a thing or two about making parts in what is arguably one of the most controlled and regulated industries in the world. We have consistently looked for ways to both increase our internal capabilities and our local vendor network to meet a developing and forward-thinking manufacturing market. See Our Latest Blog Post on Laser Cutting Here

Laser Cutting

Metal Stamping

Router Cutting

Robotic Polishing

Ultrasonic Cleaning

Photo Etching

UV Screen Printing

Laser Engraving

Polyurethane Doming

Package Printing

Injection Molding

CNC Machining

STANDARD MATERIALS

Let’s face it, finding the perfect material can be as challenging as finding the perfect parking spot. Our team experienced in material selection to meet your quality, cost, and performance goals, let us help you find the perfect start to your project. Learn More Here

304 Stainless Steel Sheet

Polycarbonate Sheet

Aluminum, Various Grades

Carbon Fiber Sheet

ABS

Acrylic Sheet

EPDM

PTFE Sheet

Polyester Sheet

Automotive Grade Pressure Sensitive Adhesives

Engineering and quality

Quality begins and ends with people. With an in-house Engineering department well versed in coordinating efforts with your internal team, we are designed to maintain and document the development process, from product concept to approved first article. But it doesn’t stop there, with a trained and empowered workforce with eyes on every stage of the process, we ensure quality is at the forefront as a parts travel throughout or manufacturing and distribution facilities.

Full Engineering Department with CAD modeling &

3D rapid prototyping capabilities

QC Department monitors inspections, GD&T, & SPC

Inhouse and Independent product testing

AIAG industry process and documentation capabilities

PPAP, ISIR, SPAN, and AAR processing

Conflict Mineral Reporting Requirements

NQC Supplier Assurance annual filing

EU packaging standards

IMDS Reporting Requirements

California Proposition 65 reporting

USMCA and EU trade documentation compliant

Internal Gage and Fixture Calibration

Inhouse Product and Packaging Design

Customer service

Although this business started with a pad, paper, and a landline, we are ready to meet your unique information system requirements. Whether is ordering over the phone or sending a purchase order via EDI, we are here to help. We pride ourselves on not only a quality product but quality service- ensuring that a competent sales and admin team is just a phone call or email away.

Utilization of 11 unique EDI platforms for seamless communication with customers from order placement to ASN/Delivery and Invoice

100% on time delivery for Port Inclusion and 96% on time delivery for Aftersales from our 18,000 Sq. foot, FIFO distribution center in Lake Forest, CA USA

Award winning supplier for variety of OEM customets

Custom Packaging/Printing and Master Carton Design and Development Capabilities utilizing minimal, recyclable materials

Adherence to complex customer specific routing & packaging guidelines for 20+ unique customers

AIAG, Odette, & other customer specific transportation documentation

Ship Domestic & International via FedEx, UPS, DHL, LTL, Ocean & Air

ISO 9001:2015 Documentation for all processes.